Durston | Jewellery Tools amp; Rolling Mills | Fast Global

Durston Tools The Global #1 Maker of Rolling Mills amp; Jewellery Tools. Buy online with fast global delivery amp; excellent customer service.

WhatsApp)

WhatsApp)

Durston Tools The Global #1 Maker of Rolling Mills amp; Jewellery Tools. Buy online with fast global delivery amp; excellent customer service.

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

January 2016 marked the 50th anniversary of the company. WELCOME TO POWEROLL Manufacturers of world class sports field rollers. POWEROLL rollers are manufactured by Power Precision amp; Fabrication Ltd (established 1966) and since the first one rolled off the factory floor in 1997 have continuously developed to become the finest and most versatile selfpropelled grass rollers on the

Shop from the world''s largest selection and best deals for Ball Mill in Milling Machines. Shop with confidence on eBay!

Angular contact ball bearings . Single row angular contact ball bearings . Double row angular contact ball bearings . Fourpoint contact ball bearings . Selfaligning ball bearings . Thrust ball bearings . Angular contact thrust ball bearings . Thin section bearings . Roller bearings . Cylindrical roller bearings . Single row cylindrical roller

Jar Mills (Roller Mills, Pot mills, Ball mills) G90 SERIES G series Jar Mills are used to grind ceramic (and other) materials in grinding jars of varying capacity. Technical data. Single Jar Mill G90 Overall size: Width 450mm approx., Length 650mm approx., and Height 330mm approx. Powered by a 1/3 HP electric motor which drives a rubber cov

Home gt; Laboratory gt; Sample Preparation gt; Mixing and Homogenisation gt; Grinding/Milling gt; Planetary Ball Mill Planetary Ball Mill Retsch Planetary Ball Mill PM 100 For 120V

Lab Rapid Ball Mill. Lab Glove Box / Operation Box. Centrifuge Series. Vibrating Screen Series. CONTACT. Tel: . Fax: . Mobile: . Email1: mills Lab Roll Ball Mill. Lab Jar Mill. Lab Roll Ball Mill. Liner Roll Ball Mill. Large Roll Ball Mill. Light Roll Ball Mill.

Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

Ball Mills. Ball mills reduce the particle size of sample by using impact energy. The energy from the impact of the moving balls beaks down the sample until the final required fineness is achieved. We are able to offer two solutions: the Pulverisette 0 vibratory mill and the Pulverisette 23 mini mill.

Hunts Roller Mill quot;If the item is defected by the processing of postage,buyer has up to days from date of receipt for exchange of a new onequot; vgc these are all used, with some very light marking, but all very clean with good threads and ready to use. lovely condition mill and mixer pto driven been stored

Ball mills can be designed to operate continuously (fed at one end of the system and discharged at the other), or on a batch basis for smaller, or intermittent volumes. They can also be operated either on a standalone basis (opencircuit grinding) or in conjunction with a classifier which returns oversize product to the mill for further grinding (closedcircuit grinding).

Ball Mill Vs Roller Mill. Ball mill a typical type of fine grinder is the ball milla slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls ball mills normally operate with an approximate ball charge of 30.

The Largest UK stockists of Loose Ball Bearings and Rollers in a wide variety of materials and ready to ship worldwide. Excellent prices and Free UK Delivery. We use cookies to improve user experience, and analyse website traffic. For these reasons, we may share your site usage data with our analytics partners.

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

Ball mill for sale New Lanark Mills Aran Yarn Wool/Silk 700g (5 x new, 2 x used balls): #163; | Vintage Bodum Ball Boy Pepper Mill: 7 #163; | Bundle of 7 x Tin t| https://

#0183;#32;Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

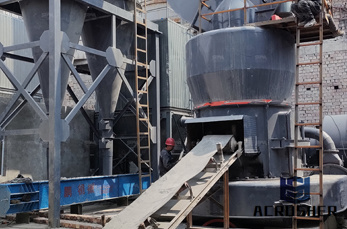

Comparing ball mills and VRMS for cement grinding World Cement. Feb 26, 2013 The comparative advantages of ball mills and VRMs in cement grinding. Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing. Written by Mark Mutter, JAMCEM, UK

WhatsApp)

WhatsApp)