Reducing Grinding Energy and Cost Magnetite Iron Ore

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study. followed by a ball mill and pebble crusher in a SAG/AG, ball mill circuit for most efficient use. Achieving consistent

WhatsApp)

WhatsApp)

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study. followed by a ball mill and pebble crusher in a SAG/AG, ball mill circuit for most efficient use. Achieving consistent

Gearless mill drive (GMD) technology has further expanded the use of large AG milling allowing to produce the world''s largest SAG mill of 42 in diameter drawing power at 28 MW. Today, is the world leading supplier of gearless AG mills operating globally.

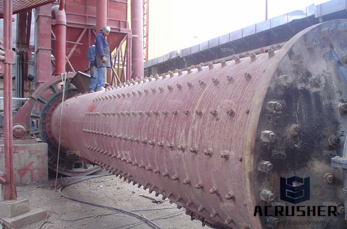

Starting as small as 13 feet (4 m) in diameter on 330 HP and as large as 24'' ( m) in diameter on 3,300 HP, the 911MPE Semi amp; Fully Autogenous Mills tumble crushed ore without iron or steel grinding media. They are used when the crushed ore pieces are hard enough to perform all the grinding. SAG mills tumble mainly ore but they use up to 15% volume of steel balls to assist grinding. Semi

SAG or AG mills. The crushed products are ground in SAG or AG mills. The selfgrinding machine can grind ore without grinding media such as iron ball, or steel rod, as long as the hardness of the ore is sufficient for the rolling ore to grind by itself. A large vibrating screen is used to sieve the ground products to separate the oversized particles.

Oct 19, 2020#0183;#32;The SAG Mill is a machine added by Ender IO. It uses Micro Infinity (#181;I) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs. Uniquely, the SAG...

Feb 01, 1994#0183;#32;The Prediction of SAG Mill Product Size Distribution In a comminution circuit based on a SAG mill followed by a ball mill, the SAG mill product size is an important design parameter that needs to be established. This is necessary to fix the size of both the SAG mill, and the ball mill. Consider the following hypothetical example.

2) Determining if the use of a single stage circuit is appropriate using defined selection criteria. Iron 3 SAG mill (815 ball charge) Variable or moderate competency ore with the competency . Service Online; What are the best ways to process ores Using a SAG mill with Dark iron balls will increase your dust output per ore drastically.

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with

This industrial scale study compares two grinding circuits operating in an iron ore process with a production capacity of 12 million tons per year. The plant has three identical parallel lines, all fed from the same feed pile. Each line has an independent grinding circuit, with two ball mills and three hydrocyclones batteries.

Hello everyone, I would like to know which one is efficient in iron ore crushing and grinding circuit: Jaw crusher+SAG mill+ ball mill 3 stage crushing + 2 stage grinding (ball mill) Regards, Suvd

SABC circuits are typically selected for plants above 2Mt/a treating moderate to high competency ores. Single stage autogenous circuits have been considered for chlorite, iron ore and serpentine based ores and have proven energy efficient at pilot and plant scale. HPGRs are being considered for large (gt;15 Mt/a) plants treating competent ores to simplify the crushing circuit and improve power efficiency.

Similar to the impeller design affecting pump capacity, the pulp lifter design affects the discharge capacity (or mill throughput) of AG and SAG grinding mills. Generally, the discharge from AG/SAG mills consists of one or both of the following components: slurry (water and finer particles) and pebbles (20100 mm). Single stage AG/SAG mills have to handle large amounts of slurry as they are generally in closed

A survey of a SAGball mill circuit processing ore from primary crushing showed size reduction of circuit (SAG) feed F80 of approximately 165,000 #181;m to flotation circuit feed (cyclone overflow) P80 of 125 #181;m. The total specific energy input for the two milling stages was kWh t 1.

sag mill circuit in iron ores; Latest Projects. K Series Mobile Crushing Plant. K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher. Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and

This industrial scale study compares two grinding circuits operating in an iron ore process with a production capacity of 12 million tons per year. The plant has three identical parallel lines, all fed from the same feed pile. Each line has an independent grinding circuit, with two

grinding circuits, ball and rod mill circuits, and crushing circuits are also available for testing and design purposes. Inplant audits allow modeling and simulation of existing plants to assist in optimization. Rotary scrubbers and attrition scrubbers are available to test lateritic iron ores. physical mineral separaTion / BeneficiaTion

Jan 01, 2016#0183;#32;These results were confirmed by tests in the Canadian Malartic plant where the cyanide addition was moved from the SAG mill to the leaching tanks resulting in a 20% savings in cyanide in grinding circuits can benefit gold processing by decreasing gold lockup and by reducing leach time. for ores requiring

The mills can be operated in open circuit, feeding downstream secondary grinding, or operated in closed circuit as single stage mills generating a finer product size. Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream

Sag Mill Circuit In Iron Ores Choosing a SAG Mill to Achieve Design Performance. SAG mill itself and not on the test work program. Stated another way, money invested in a large SAG mill is an investment that can produce handsome returns if extra production is needed or simply to give the mine the option to mill the hardest

2 AG mill + a recycle crusher Competent ore relatively homogenous. The recycle crusher is used to balance the rate of media breakage within the mill Kambalda, Olympic Dam, Sino Iron 3 SAG mill (8 15% ball charge) Variable or moderate competency ore with the competency suiting the selected grind size Tarkwa, Leinster, Golden Pride,

WhatsApp)

WhatsApp)