rod mill vs ball mill

Grate discharge ball mill can discharge dry grinding and also for the first grinding system. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter.

WhatsApp)

WhatsApp)

Grate discharge ball mill can discharge dry grinding and also for the first grinding system. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter.

The study of pulpdischarge arrangements onpebble mills,which has been, and still is,ofparticular interest to the principal author of this paper, hasextended overmany years. Commencing at the now ball mills. A primary pebble mill was run at 136, 123, 99, and 91 per cent ofcritical speed and compared with astandard millrunning

Metallurgical ContentTypes of Ball Mills Ball Mill GrindingExample of Plant Capacity GainsBall Mill SpecificationsCompare Type of Mill DischargeGrate Discharge Ball Mill CapacitiesGrate Discharge Ball Mill Arrangement amp; Dimensions Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is

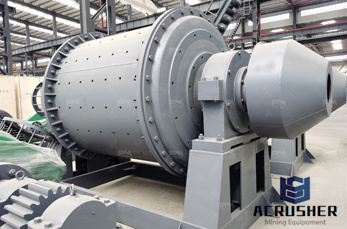

3 Energysaving grate ball mill adopts whole milling house which makes it easy for construction and installation 4 Energysaving grate ball mill has bigger discharge opening and huge processing capacity 5 Energysaving grate ball mill is equipped with oilmist lubrication device which guarantees smooth operation of gears...As a leading global manufacturer of crushing equipment, milling

21/11/2014#0183;#32;Overflow verses grate discharge ball mills: an experimental investigation Overflow Discharge Ball Mill in Operation Mineral Processing Duration: 1:42. Himanshu Srivastav 24,642 views.

Cost Effective Ball Coal Mill Grate Discharge Ball Mill for sale MOQ: 1 Set 10, /Set

Grate discharge Dry Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure

Overflow VS Grate Discharge Ball or Mill Why Retrofit

High efficiency grate ball mill for sale. ISO9001 approved grate type ball mill meet your ore grinding needs. Get free material grinding test now!

Grate Discharge Ball Mill. Working principle of grate discharge ball mill I try to explain how the slurry is discharged from the grate ball mill, or how it works. Its working principle is that the slurry flows through the grate, just like the screen on the other side of the grid. When the mill rotates, the screen is a vein like a pump impeller.

Here I try to explain how ground slurry is discharged from a grate ball mill (or SAG). How it works is, the slurry flows across the grate as it would a screen panel. On the other side of the grate/screens are veins like a pump impeller. As the mill turns/rotates the slurry is pumped out and discharged. Discharge Grates The natural flexibility of rubber has allowed rubber manufacturers to

It has been widely accepted to go for grate discharge ball milling when a coarse product is preferred or to avoid production of extreme fines, but overflow discharge mills are preferred for their simplicity of design and production of finer product. In grate discharge mills the product is discharged primarily due to hydraulic gradient from the feed end to discharge end.

Grate Discharge Ball Mill Used in wet and dry grinding in both open and closed circuits, a grate discharge ball mill (sometimes known as a diaphragm discharge mill) incorporates a slotted discharge diaphragm with lifters at the discharge end of the mill. The diaphragm, or grate, serves to

ball mill discharge types srpccoin Ball mill 1456 is designed for dry grinding of ore and nonmetallic raw materials Overflow VS Grate Discharge Ball or Mill Mill grinding Wikipedia Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is .

Abstract. Pulp lifters, also known, as pan lifters are an integral part of the majority of autogenous (AG), semiautogenous (SAG) and grate discharge ball mills. The performance of the pulp lifters in conjunction with grate design determines the ultimate flow capacity of these mills. Although the function of the pulp lifters is simply to transport the slurry passed through the discharge grate into the discharge

Grate Discharge Ball Mills Grates can be added to the discharge end of the ball mill to facilitate a steeper pulp gradient which helps to prevent overgrinding. 2040 Ball Mills Ball Mills Brochure 06/02 24 ft. x 30 ft. 14,000 HP Ball Mills .

2. Dry Type Ball Mill: Some discharge materials are extracted by air flow, and the mill and wind grading device are closedcircuit. For example, cement mill adopts automatic discharge. (7) Types on the Basis of Cylinder Direction. 1. Vertical Ball Mill: The vertical ball mill is a new type of ball mill which places the cylinder upright. Through a large number of experiments, it is found that the vertical ball mill has the

The ball mill is used to grind many kinds of mine and other materials, or to select the mine. discharge ball mill features: 1) Ball mill an efficient tool for grinding many materials into fine powder. barite production line equipment barite grinding ball mill. US

With grate discharge mills typically SAG, AG and ball mills the conventional relining process at the discharge end usually involves removing the dischargers and grates, replacing with new lined versions and hammering in large, long bolts through the layers to secure the liner components.

03/04/2019#0183;#32;Ball Mill, Grate Discharge, Toll Processing. This video is unavailable. Watch Queue Queue

WhatsApp)

WhatsApp)