Working principle of Ball Mill /ball cement milling

#0183;#32; Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

WhatsApp)

WhatsApp)

#0183;#32; Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

Principle Of Ball Milling As Used For Grinding Of . A grinding ball mill is a type of grinder used to grind and blend materials for use in mineral processes a grinding ball mill works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell.

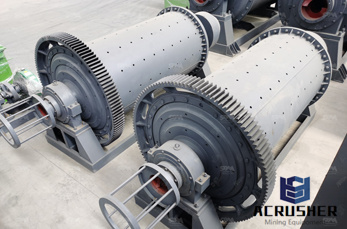

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

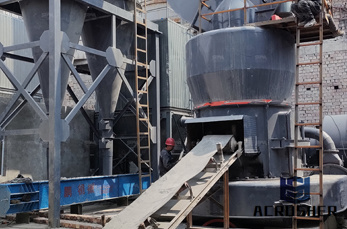

Here we would like to share the working principles and advantages to let you have a good understanding of ceramic ball mill. Ceramic ball mill is mainly used for material mixing and grinding, and this machine can be used both by dry and wet process to mill, mix and discharge material such as feldspar, quartz and clay.

#0183;#32;Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

grinding machine working principle ppt La Mining. Ball mill grinding machine, operation, working principle, parameter, Nano Ball Grinding Ceramic Industry Buy Ball Mill For Ceramic Industry,Ball

Working Principle of Ball Mill For Ceramics After the motordriven reduction gear device through the rotary cylinder, the cylinder body and the ball when the crushed ore rotary cylinder by centrifugal force and friction linings are brought to a certain height due to gravity, and diarrhea will produce the falling down, the ore under the impact and abrasive gradually being crushed.

The working principle of ball mill Meetyou Carbide

Ball Mill Working Principle And Main Parts. Ball Mill Working Principle. To be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia and centrifugal force the effects of friction making it attached to the cylinder liner on the

Ball mill working principles Ceramic ball mill working Ceramic ball mills Ball mill critical speed working principle Ball nose end mill grinding Ball mill used for feldspar Round ball mill for industrial Interested in watching more videosClick here to filter results Have a Question Ask our expert.

WhatsApp)

WhatsApp)