Step Production Line Of Cement

4 step production line of cement. Cement Wikipedia, the free encyclopedia. A cement is a binder, a substance that sets and hardens independently, and can bind other materials together.

WhatsApp)

WhatsApp)

4 step production line of cement. Cement Wikipedia, the free encyclopedia. A cement is a binder, a substance that sets and hardens independently, and can bind other materials together.

Aug 26, 2019#0183;#32;The new dryprocess cement production line technology was developed in the 1950s. So far, in Japan, Germany and other developed countries, the production rate of new dryprocess cement clinker with suspension preheating and predecomposition as the core accounted for 95%.

After the initial setting time of the cement, the cement becomes stiff and the gypsum retards the dissolution of tricalcium aluminates by forming tricalcium sulfoaluminate which is insoluble and prevents too early further reactions of setting and hardening. 2 O 3 + xCaSO 2 O = 2 O 2 O. 4. Storage and packaging

4 step production line of cement Magnagrecia Viva Steps of Cement Production Process Flyer Cement In the cement production process, each ton of portland cement requires the grinding of at least 3 tons of materials which include all kinds of raw materials (fuel, clinker, gypsum, mixture, etc.).

Global cement production is expected to increase from billion metric tons in 2010 to billion metric tons in 2030. In China, the cement production in 2018 amounted to some million

#0183;#32;4. Burning of the Bricks. It is the very important step in manufacture of bricks. Bricks may be burnt by two distinct methods given below. Burning in a clamp or Pazaw known as clamp burning; Burning in a flame kiln or Bhatta known as kiln burning; In clamps, one batch of green bricks is heaped along with firewood, coal etc. and sealed with clay.

In Europe, cement production decreased by % from 1990 to 2012, whereas CO 2 emissions decreased by %, showing an improvement in the cement production (CEMBUREAU, 2014). However, to reach the objectives of various sustainability programs, further efforts must be made in order to improve every step in the concrete production line.

Domestic cement production has been increasing steadily, from million tons in 2010 to about million tons of Portland cement in 2014 according to the Geological Survey 2015 Cement Mineral Commodity Summary.

#0183;#32;Production Line . A production line is a traditional method which people associate with manufacturing. The production line is arranged so that the product is moved sequentially along the line and stops at work centers along the line where an operation is performed. The item may move along some kind of conveyor, or be moved manually by staff or

Almost every construction work requires cement. Therefore, the composition of cement is a matter of great interest to engineers. For understanding cement composition, one must know the functionality of Cement ingredients. By altering the amount of an ingredient during cement production, one can achieve the desired cement quality. Ingredients of

Another cement industry trend is the concentration of manufacturing in a smaller number of largercapacity production systems. This has been achieved either by replacing several older production lines with a single, highcapacity line or by upgrading and modernizing an existing line for a higher production

Production line is the new car factory management/simulation/tycoon game from Positech Games, the developers of Democracy amp; Gratuitous Space Battles, and publishers of Big Pharma. This game is designed to appeal to the efficiency geek in all of us, the person who cannot help but organize things for maximum performance.

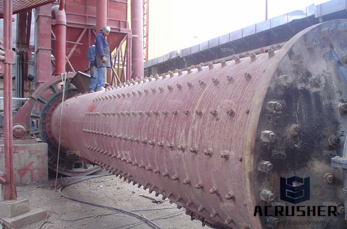

4 step production line of cement In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant

1. Dry Process of Manufacture of Cement. Following are the main steps in this process of cement manufacturing: i. Treatment Of Raw Materials. ii. Burning of the Dry Mix. iii. Grinding of the Clinker. iv. Packaging and Storage. Youll know all the process below in details. (i) Treatment of Raw Materials:

4 In the calculation of the production loss of the complete cement production line and clinker production line, the production loss of coal should be calculated at %, and the production loss of other materials should be calculated at %. The production loss of all materials in the cement grinding station shall be calculated at %.

is a platform for academics to share research papers.

Dry Process Cement Production Line. Capacity: 300 t/d8000 t/d Type: new dry process Materials: Limestone Clay Gypsum etc Equipment: Cement MillCement KilnBag Filter Compared with other production lines the power consumption rate of the new dry process cement production line is about 20%35% which greatly reduces the production cost for customers and improves the comprehensive

cement industry energy and economic data were collected, and analyzed. The remainder of this report is organized as follows: Section 2 summarizes California cement industry statistics Section 3 provides an overview of the cement production process Section 4 presents results of interviews with cement industry customers

WhatsApp)

WhatsApp)