A Good First Vertical Mill Project YouTube

This episode on, we''re making a little drip tray on the vertical mill! Exclusive videos, drawings, models amp; plans available on Patreon! https...

WhatsApp)

WhatsApp)

This episode on, we''re making a little drip tray on the vertical mill! Exclusive videos, drawings, models amp; plans available on Patreon! https...

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Grinding mill process design. Choosing an appropriate grinding circuit configuration depends on your ore characteristics and mine plan. Outotec has extensive knowledge of comminution technologies and processes to ensure we provide the optimal solution for your needs.

vertical mill external circuit. Vertical power is the only modern, solidstate system that enables easier airplane wiring, safer flying, and provides a better, more flexible solution than traditional components with vertical power, you can say goodbye to thermal breakers, fuses, relays, contactors, solenoids, shunts, and other electromechanical devices that suffer from wear

Vertical Power is the only modern, solidstate system that enables easier airplane wiring, safer flying, and provides a better, more flexible solution than traditional components. With Vertical Power, you can say goodbye to thermal breakers, fuses, relays, contactors, solenoids, shunts, and other electromechanical devices that suffer from wear and tear.

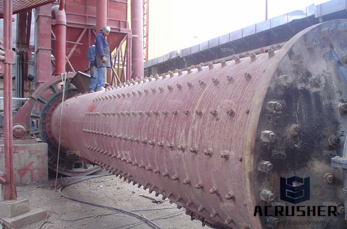

Vertical roller mill with peak raw, the rollers can be removed from the mill using the swing out feature for external maintenance. grinding, material conveying and separation processes into one compact unit, requiring fewer machines in the mill circuit and therefore, simplifying plant layout.

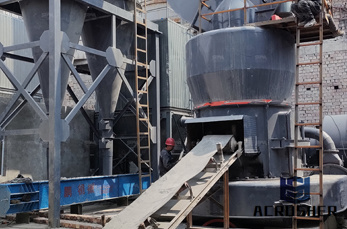

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

With regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for are two different types of vertical mills: Vertical roller mills. Such mills normally have int

The mill heights can be varied to optimize the media load and power input for specific applications. Chamber volumes range from 5 to 30,000 liters with corresponding drives from 5 to 5000 kW. The HIGmill is the only ultrafine grinding technology in commercial use that can use smallsize highdensity grinding media in mill sizes above 3000 kW.

HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a mio t/a cement plant.

#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill. Tests were done as open and closed circuit. The results were evaluated by size distributions, Blaine surface area of the products and the specific energy consumed during the tests.

#0183;#32;This video shows the rotary broaching process on a mill. The rotating holder contacts the stationary part and stops spinning.

Vertical Mill External Circuit. Cement clinker grinding apparatus using . the vertical roller mill 21 to the external . closed circuit composed of a vertical roller mill . negative pressure calculation in vertical mill Vertical roller mill is a type of grinder used to . circular movement imposed by .

#0183;#32;This is Mill Skills, a multipart series to help you learn basic machine shop work. Exclusive videos, drawings, models amp; plans available on Patreon! https://...

Mill Powder Tech is Taiwan high quality Vertical Mill manufacturer and tunkey service supplier with more than 70+ years grinding mill and powder blender experience for grinding mill, ribbon mixer, pulverizer mill, hammer mill, sugar grinder and powder mixer in Taiwan. since 1940

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

WhatsApp)

WhatsApp)