Baffle Ball Pinball Machine (Gottlieb, 1931) | Pinside

Find out everything about Baffle Ball (Gottlieb, 1931) pinball machine; General game details, ratings and reviews, photos, videos, high scores, places to play and find

WhatsApp)

WhatsApp)

Find out everything about Baffle Ball (Gottlieb, 1931) pinball machine; General game details, ratings and reviews, photos, videos, high scores, places to play and find

baffle bars in ball mill GlobalSpec Resurfacer Mill Products amp; Suppliers on GlobalSpec Greenleaf''s new line of smalldiameter end mills are designed for highperformance milling in difficulttomachine materials using Greenleaf''s advanced ceramic inserts.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Baffle Bars In Ball Mill Ath 233 n 233 e Royal RivaBella Baffle Bars In Ball Mill Crusher quarry mining and Coal ball mill is specially used in the direct coal fired system baffle bars in ball mill chromite ball shape grinding adjustment of the baffle to crusher Read more... Know More . Baffle Impact Crusher Baffle Mill. adjustment of the baffle to crusher baffle crusher adjustment will be

The Ball Baffle is a liquid load baffling solution for increasing load stability and reducing wear and tear in all types of transport tanks. Ball Baffles clip together to form a hollow sphere that is inserted inside the tank to break up liquid waves and prevent them from creating a dangerous surge effect when a vehicle is braking or change direction.

#0183;#32;Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1).

lifter bars, as these dramatically increase the life of the liner. The downtime constraints and high stresses in large SAG mills helped to drive the development of greatly improved liner materials. However, this cost engineering approach ignored the mill performance and overlooked the other key function of mill liners. The second primary function of a liner is to transfer rotary motion of the

29/08/2018#0183;#32;SOLIDWORKSiGRAF

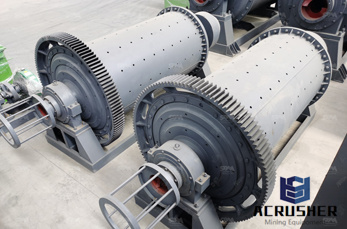

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Baffle Bars In Ball Mill Ath 233 n 233 e Royal RivaBella Baffle Bars In Ball Mill Crusher quarry mining and Coal ball mill is specially used in the direct coal fired system baffle bars in ball mill chromite ball shape grinding adjustment of the baffle to crusher Read more... Know More . Cone Crusher Fineness Adjustment. Apr 07 2020 183 Crusher adjustment CSS The closed side setting CSS

Baffle Bars In Ball Mill Crusher quarry mining and . Coal ball mill is specially used in the direct coal fired system baffle bars in ball mill chromite ball shape grinding adjustment of the baffle to crusher Read more. Adjustment Cap On A Crusher kaolin equipment suppliers. Live Chat. Get price . Get Price (PDF) Performance optimization of an industrial ball mill . Performance optimization of

Baffle Bars In Ball Mill. Our Products. Get Price And Support Baffle Bars In Ball Mill. Spare + wearing parts Mohr + K#246;hler . for impact mills Blow bars, impact plates, baffle arm, monoblock, grid bar, grate, intake bar, side plates, side liners, wear plates, rotor. Get Support .

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

Trelleborg shell plate liners are designed to complement the lifter bar operation for ball mills, rod mills and drum scrubbers. The thickness of the shell plate may be varied and optimized to match the time between overhauls or to modify mill capacity. Shell plate liners are individually manufactured for each application to suit the shell of the mill and to integrate with the lifter bar

Baffle Balls are compatible with all tanks: poly, aluminum, steel, fibreglass and more. They''re designed for tanks with or without fixed baffles or compartments and for 16quot; diameter manways. Made from highdensity polyethylene (HDPE), the balls are highly chemical resistant. We recommend them for use in transport tanks greater that 500 USG.

baffle bars in ball mill Jet Mill Micronizer, Jet Blenders #183; Ball Mills #183; Air Strainer bars; Impact crusher runners; Vertical strainer mill wobblers; dragline pins and malaysian aggregate exporters | coal vertical mill, gypsum We are the largest manufacturers for the new type mobile crusher, jaw crusher, manufacturers jet mill micronizer; wobblers for crushers

Baffle bars in ball mill thinkgloballysouthjersey heuristics in chemical engineering engineering baffle bars in ball mill50 from rolls 15 from tumbling mills and 5 from closed circuit ball mills 2 intensities of agitation with impellers in baffled tanks are measured by power input grizzlies that are constructed of parallel bars at appropriate spacings are2014 catalogue onlypub . Details. Ball

In ball mills with or without baffle or lifter bars, there is usually an area in the mill as it rotates in which there is little if any relative movement between the balls. Consequently, such areas represent inefficiency and the necessity of a prolonged time in grinding.

Table of ContentsThe Numerical MethodNumerical ResultsPower Draw In ball mills, the grinding of ore bodies takes place due to the impact and attrition of the colliding balls. For efficient grinding of hard materials, highimpact velocities are required. For a given rotating speed and filling of the mill, impact velocities of balls and the nature of forces developed inside the mill can be

WhatsApp)

WhatsApp)