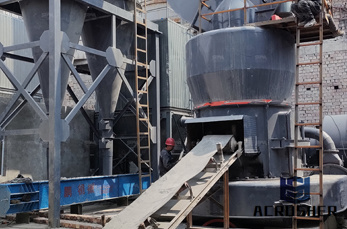

machinery of cement industry

Cement Plant amp; Machinery Walchandnagar Industries. Overview. Walchandnagar Industries Limited (WIL) Cement Division started its journey in 1963 and since

WhatsApp)

WhatsApp)

Cement Plant amp; Machinery Walchandnagar Industries. Overview. Walchandnagar Industries Limited (WIL) Cement Division started its journey in 1963 and since

cement plant equipments manufacturer and suppliers of clinker grindin

Raw materials used in cement industry are: limestone; silica; alumina; gypsum. Question 47. Write down the locational factors of cement industry. Answer: Factors which affect location of cement industry are: Availability of raw materials which are heavy and bulky,, limestone, silica, etc. Availability of coal and electric power. Rail transportation.

Like industries from aviation to financial services, the cement business has been on a big is beautiful march over the past five decades. A rush of expansions, mergers, acquisitions, and consolidations has reshaped the industry. The model has not necessarily created value for companies or their investors.

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad. We undertake complete responsibility for the design, engineering, manufacture, supply,

The electronics industry covers a wide range of products from transistor sets to television, telephones, cellular telecom, telephone exchange, radars, computers and many other equipments required by the telecommunication industry.

Cement | Voith. Cement is the most important component for manufacturing concrete. Cement Machinery Industry. The Indian cement machinery industry is engaged in the manufacture of complete cement plants with capacities upto 10,000 TPD. based on dry processing and

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

Clinker production is the most energyintensive stage in cement production, accounting for over 90% of total industry energy use, and virtually all of the fuel use. Fuel use for clinker production in a wet kiln can vary between and MBtu/short ton clinker (Worrell and Galitsky, 2004).

Social Science Class 10 Important Questions Geography Chapter 6 Manufacturing Industries. Iron and Steel industry, Cement industry. Iron and steel, cement, machine tools, petrochemicals, etc. Question 11. Explain the types of industries on the basis of ownership and give one example of each.

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water as

Cement Grinding 6. Conclusion Glossary Bibliography Biographical Sketch 1. Introduction The cement production industry is one of the most fundamental industries from several points of view. Its product can be found almost everywhere in the everyday life, and the industrial society cannot survive without cement. This industry is a great power

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products amp;hightech products. The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheater.

The Japanese cement industry commenced the actual production of cement in 1875. The decades since have witnessed the relented pursuit of technological development, economic growth as a construction basic materials industry and other steady expansion and progress.

Lubrication Strategies for the Cement Industry. Lubrication in the cement industry offers some unique challenges. It''s not so much the type of equipment that is the issue but the environment in which the machinery is operating, which can vary from season to season depending on the plant''s location.

Cement Plant Machinery Walchandnagar Industries. Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad. We undertake complete responsibility for the design, engineering, manufacture, supply, project management

#0183;#32;Industry digital innovations, from advanced data analytics to intelligent networks, offer tremendous opportunity to create value and raise the efficiency of production processes. Yet few cement producers have implemented advances in any systematic way.

In the cement industry, when dry process is adopted for production, all the materials containing water such as raw material, coal and admixture need to be dried. When wet process is adopted for production, coal and admixture also need to be dried, to ensure the normal process of the powder grinding work.

Important Machinery In Cement Industry. Importance of screening and sieving in cementconstruction equipment used in cement industrycemtech cement industry conferences how important mining in cement plantmilling machinary tube mill in cement industrymachines for cement industry cement production linecement equipmentcementassembly line of limestone stimulate cement production machines in cement

WhatsApp)

WhatsApp)