intermittence ceramic ball mill, intermittence ceramic

offers 185 intermittence ceramic ball mill products. About 93% of these are Mine Mill. A wide variety of intermittence ceramic ball mill options are available to you,

WhatsApp)

WhatsApp)

offers 185 intermittence ceramic ball mill products. About 93% of these are Mine Mill. A wide variety of intermittence ceramic ball mill options are available to you,

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Intermittent ball mill plays an important role in . Ball Mill,Raw Ball Mill,Batch Ball MillProduct information Ball mill is the key equipment for secondary grinding after crushing. Address: Shenxia Road, Malu Industrial Park, Jiading District, Shanghai, China. Mining Ball Mill.

Hybrid Intelligent Modeling Approach for the Ball Mill Grinding Process 613 Based on the grinding theory, the populace equations and the mixer concept [3] [7] [8], together with our analysis of the dynamics of this ball mill grinding process, the ball mill model can be derived as M u Q R Q D u V = 1 + 2 + , (11) ( ) 1 1 R R R D 2 D 1 D M

Glass Cement Intermittent Ball Mill. Introduction: CIC is a leading comprehensive mill liner supplier in China. advanced production process, extensive supply capacity, superior quality guarantee and perfect aftersale service. We continually strive for perfection and all our efforts are directed towards attaining complete client

Jan 03, 2005#0183;#32;1. Introduction. Modelling of grinding mill and circuit is and continues to be a challenging theme for many researchers. Grinding models are mainly used in grinding circuit simulators for process optimisation, design of control strategies, and for the analysis of the effect of a change of operating conditions (ball size, shape, rotation speed etc.) on the mill efficiency, .

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills.

Perfect mixing ball mill model. A series of samplings were conducted around the raw mix grinding circuit, and clinker samples were taken. The data obtained from the plant sampling was fitted with the perfect mixing ball mill model using the assumption that the mill contents are perfectly the steady state mineral processing

Planetary Ball Mill. The PM 100 CM operates with a speed ratio of 1:1 (centrifugal mode). The centrifugal forces produced by the rotation movement the sample and the grinding balls against the inner wall of the grinding jar, where size reduction takes place primarily by pressure and friction. Planetary Ball MillS 5 Planetary Ball Mills

2018 The Best Selling Intermittent Sag Mill Powder Ball Mill Iso Certified, Find Complete Details about 2018 The Best Selling Intermittent Sag Mill Powder Ball Mill Iso Certified,Intermittent Sag Mill Ball,Intermittent Cone Ball Mill,Powder Ball Mill from Mine Mill Supplier or ManufacturerHenan Engineering amp; Technology Co., Ltd.

3 # lb capacity media ball mill. Perfect size for the small hobbyist to mill black powder, rocket pr.. Add to Cart. Add to Wish List. Compare this Product. Ball mill 6 Lb capacity. 6 lb capacity double barrel ball mill. Perfect size for milling 2 different comps at once in separat..

Product Name: Intermittent Cement Ball Mill ; Model: 600#215;840 ; Effective Volume: #179; ; Rotary Speed: 55r/min

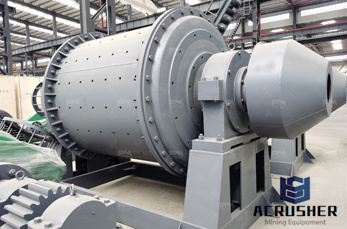

Intermittent Ball Mill. The barrel of the intermittent ball mill is inlayed with ceramic, rubber and silica lining plate, and it has many benefits of even products size, energy conservation and saving electricity. Besides, it is suitable for both wet grinding and dry grinding, and can selfcontrol the size depending on the grinding time.

China Feldspar Intermittent Type Ceramic Ball Mill, Find details about China Ceramic Ball Mill, Intermittent Ceramic Ball Mill from Feldspar Intermittent Type Ceramic Ball Mill Zhengzhou Hengxing Heavy Equipment Co., Ltd.

Oct 01, 2001#0183;#32;A comminution model is developed for ball mills using the principles of perfect mixing. Tlines are developed from data arising from single particle breakage tests using a laser monitored, twin pendulum breakage device. A t parameter is developed that produces a family tlines which can be modeled using linear equations.

5. The appropriate model, liner, and medium type can be selected according to factors such as the specific gravity, hardness of the material and the output of the ball mill stone grinder. The above are the production advantages of continuous ball mills and intermittent ball mills. Users can choose suitable equipment according to the actual

Our Ball mill series: In our Factory Workshop, there are Ball mill, cement ball mill, coal ball mill, raw material ball mill, rod ball mill, intermittent ball mill. etc, in recent years, our company have developed many kinds of ball mill, such as *60m ball mill.

WhatsApp)

WhatsApp)