Pulverizers 101: Part I POWER Magazine

Aug 01, 2011#0183;#32;A bowl mill spring or hydraulic preload for this size of mill will also be about 20 tons of pressure. LowerHGI fuel and fineness of greater than 75% passing of

WhatsApp)

WhatsApp)

Aug 01, 2011#0183;#32;A bowl mill spring or hydraulic preload for this size of mill will also be about 20 tons of pressure. LowerHGI fuel and fineness of greater than 75% passing of

Does Coal Washing Help GHG Emissions Reduction? (presented March 10, 2000 by S. Padmanaban, USAID/India at CPI 2000 New Delhi) Typical Emissions using raw coal (42%) in a standard Indian coal fired power plant. Carbon Dioxide kilograms carbon

Bowl mills are used for pulverizing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

on 70% of the coal passing through a 200 mesh screen. Mills are capable of grinding harder coal with higher percentage moisture content and can reduce the product fineness in excess of 90% passing a 200 mesh screen at a reduced output capacity. The feed size of the coal to the mill should be precrushed to 1 top size. Available capacity size

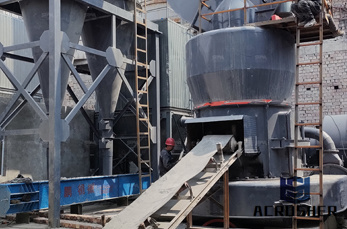

manufacturer of crusher and bowl mill. Industrial pulverizing equipment your solution to size reduction request a quotesince stedman machine company has been a consistent leader in size reduction technology and industrial crushing equipment manufacturingOur sizereduction equipment is designed to increase profits by maximizing the production of marketable product and reduce equipment down time

The Raymond#174; Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (lt;5%R75) with a wide

introduction to bowl mills Coal is the one of the most dominating energy source because of its cost, availability and transportability. Pulverized form of coal has made modern steam generating units highly thermal efficient, reliable, safe and able to efficiently use of lowgrade coals.

When enough coal has been reduced in size, it will flow over the top of the dam ring (retention ring). Coal Pulverizer Inlets and Outlets Louvres ( nozzle ring ) around the outer perimeter of the grinding table allow hot gas to flow into the grinding mill through the mill base.

NomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill. If the number is odd then its deep bowl mill 3 number of rollers three nos. X frequency of power supply 50 USA x means 60 cycles. R Raymond, name of the inventor

Mill outlet temperature control for bowl mill and tube mill. How breakage energy and force are applied in the mill in order to achieve size reduction in an efficient and effective manner. This is a matter of design and performance of mills and the main subject of this section; Power saving in coal mills and reduction of rejects.

A rotating throat pulverizing mill has a soft steel vane wheel which rotates with the control bowl for classifying purposes. Wearresistant vane liners slide onto the vanes to protect the upper surfaces thereof and are held in place, in part, by integral clips which underlie the vane plates and, in part, by wearresistant cap plates which are welded to a flush upper flange of the vane wheel.

The basic features of Bowl Mill (Puveriser) supplied by BHEL are: Medium speed range of 40 to 60 rpm. Motor speed range of 600 to 1000 rpm. Speed reduction by two method : Single stage worm amp; worm wheel set Planetary Gear Box; Input coal size is 25 mm while output is 6575 micron. Crushing of coal by replaceable bull ring segment and

The coal is transported to first crusher and the coal size is reduced to 300 mm. The coal is then transported to second crusher and the coal size is reduced to 80 mm Now the coal is feed to the 3rd crusher and the coal is 20 mm size. After this process the coal is the coal is then transported to the pulveriser and then the coal is pulverised.

For example, forcing coal against coal. Bowl mill. Similar to the vertical roller mill, it also uses tires to crush coal. There are two types, a deep bowl mill, and a shallow bowl mill. High Size reduction rates for relatively coarse particles were firstorder and increased linearly with power input to the mill. Optimum milling medium

Aug 29, 2010#0183;#32;Bowl mills are used for pulversing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

The Raymond#174; Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (lt;5%R75) with a wide range of capacities from 24 to 150 stph.

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl grinding mill types include the ball tube mill, hammer mill, ball and race mill, and, roll and ring mill.

TYPES OF PULVERISERS BASED ON PRINCIPLES OF PARTICLE SIZE REDUCTION IMPACT ATTRITION CRUSHING PULVERISERS USE ONE, TWO OR ALL THE THREE PRINCIPLES. TYPES OF PULVERISERS Speed. Type. Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill.

WhatsApp)

WhatsApp)