Replacement of river silica (or) sand with rock dust at

In such a situation the Quarry rock dust can be an economic alternative to the river sand. Quarry Rock Dust can be defined as residue, tailing or other nonvoluble waste material after the

WhatsApp)

WhatsApp)

In such a situation the Quarry rock dust can be an economic alternative to the river sand. Quarry Rock Dust can be defined as residue, tailing or other nonvoluble waste material after the

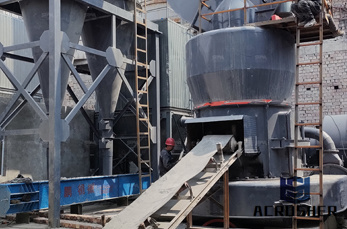

Stone dust is a waste material obtained from crusher plants. It has potential to be used as partial replacement of natural river sand in concrete. Use of stone dust in concrete not only improve the...

quarry dust as replacement of river sand. Quarry dust can be described as the residue or tailing material after the extraction and processing of rocks and that forms fine particles less than Quarry dust constitutes 2025 % of the output of rubble crushing (Information gathered form the quarry owners). Smooth round shape of river sand makes bond

#0183;#32;In light of the scarcity of natural sand resource in several districts in our country,this paper proposes the thoughts to replace river sand with rock dust to compound C20C45 concrete,discusses the influences of rock dust on concrete working performance and the design concept of concreterock dust mixture ratio,and shows by experimental results that,rock dust concrete has well performance.

have also been used as partial replacement of river sand. However, there is a reluctance to use quarry dust as replacement of river sand. Quarry dust can be described as the residue or tailing material after the extraction and processing of rocks and that forms fine particles less than

Another alternative is by using quarry waste to replace the use of natural sand. Quarry dust can be defined as residue, tailing or other nonvoluble waste material after the extraction and processing of rocks to form fine particles less than 6mm. Natural sand in many parts of the country is not graded properly and has excessive silt.

#0183;#32;The effects on each of these properties were examined by changing the percentage replacement of Natural River sand (NS) with crushed rock sand (CRS). An optimization study was performed to study the effect on the properties of concrete when paste content was held constant and the fly ash was considered to be powder instead of aggregates.

The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries. By replacement of quarry dust, the requirement of land fill area can be reduced and can also solve the problem of natural sand scarcity. The availability of sand at low cost as a fine aggregate in concrete is not suitable and

#0183;#32;The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in Concrete. Quarry dust, a byproduct from the crushing process during quarrying activities is one of such materials.

In India the use of quarry dust to replace river sand was reported by [2]. The use of rock dust as an alternative to natural sand was also reported by [5]. The use of up to 20% quarry waste fine as a partial replacement for natural sand in the production of concrete, in Malaysia was also reported [6].

journal papers on replacement of sand by quarry rock dust. journal papers on replacement of sand by quarry rock dust /5 1,663 ; Properties of green concrete containing quarry rock dust and . Get Price; replacement of river sand by crushed sand . replacement of sand by crushed concrete debris. replacement of sand by crushed concrete debris.

Quarry dust mixed with 3mm down size stone aggregate is a replacement for River Sand. Sand mining from some of the river is banned by supreme court. So as an alternate for this IS Code is published amp; this sand from Rock is known as Robo Sand/ Rock Sand / M Sand.

Stone crusher dust, which is available abundantly from crusher units at a low cost in many areas, provides a viable alternative for river sand in concrete. Investigations on the use of stone

#0183;#32;Portland limestone cement, river sand and quarry rock dust both of 2 mm maximum size as fine aggregate, and 14 mm crushed rock coarse aggregate were used for the concrete The particle size distribution and the physical properties of the fine and coarse aggregates are shown in Fig. 1 and Table 1 respectively. The fine and coarse aggregates satisfied the BS EN 12620:2002 + A1:2008

Quarry dust is ideal for these jobs and is expected to be the future and likely replacement for sand in construction project, since river sand is fast becoming scarce and very expensive. Strength When Needed . Sand is obtained from river beds, and is its availability is becoming challenging at

2 #0183;#32;River sand is becoming very scarce and sand mining from rivers has become objectionably excessive. It has now reached a stage where it is killing all our rivers day by day so sand mining has to be discouraged by the engineers for all type of construction.

at 50% replacement at room temperature and net strength after loss due to hike in temperature was above the recommended strength value due to 50% replacement itself. This result gives a clear picture that quarry dust can be utilized in concrete mixtures as a good substitute for natural river sand giving higher strength at 50% replacement.

Use Of Quarry Dust To Replace Sand In Concrete An . At 50 replacement at room temperature and net strength after loss due to hike in temperature was above the recommended strength value due to 50 replacement itself This result gives a clear picture that quarry dust can be utilized in concrete mixtures as a good substitute for natural river sand giving higher strength at 50 replacement

WhatsApp)

WhatsApp)