grinding process in pelletization process

Biomass Pelletization Process | BioEnergy Consult

WhatsApp)

WhatsApp)

Biomass Pelletization Process | BioEnergy Consult

grinding process in pelletization process. Beneficiation Plants and Pelletizing Plants for Utilizing . process. As shown in Fig. 1, the beneficiation process mainly comprises the subprocesses of grinding, separating and dewatering. Grinding Grinding is a subprocess of finely grinding ore in advance, such that the ground output can be physically separated into iron ore and impurities in

His process involved grinding taconite to remove gangues and upgrading the iron ore (, an ore beneficiation process). The resultant highgrade ore is in the form of fine particles, as small as or less, which are not suitable for sintering. This issue

EFB Pelletization Process,Biofuel Resource. The first step of pelletization process is grinding. EFB Pelletization process is a simple, it mainly contributes by 5 major processes, namely 1)

Pelletization an overview ScienceDirect Topics. 01/01/2012 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price.

wet grinding for ironore pelletisation process. wet grinding for ironore pelletisation process mtpy iron ore pelletizing plant incorporated with MOK108 Indurating for both iron ore wet grinding and iron oxide pellet production from BUREAU VERITAS mtpa beneficiation and

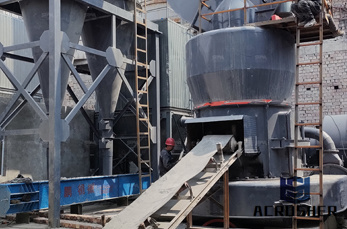

grinding process in pelletization process. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

The grinding and pelletizing process is designed as an integrated, continuous process variable speed drives on the feeders for the grinding and pelleting equipment are controlled by the amperage draw on the main motors this eliminates power overloads but still keeps the equipment operating at optimal capacity, computer controlled

6/6/2020#0183;#32;Size reduction is done by grinding using a hammer mill equipped with a screen of size to mm. If the feedstock is quite large, it goes through a chipper before grinding. The next and the most important step is pelletization where biomass is compressed against a

Quartz Stone Grinding Mill; Bucket Crusher Malaysia; Ashland Roller Mills Cuccinelli; Crusher Uk Manufacturer; pec 1525 rock crusher made in germany; Cone Crusher Mantle Price; ch sandvi cone crusher price; Gold Ore Separation Process; Government Subsidy On Stone Crusher; rotary hearth furnace iron ore reduction crusher mill chi

Grinding Process In Pelletization Process As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

The long length of EFB Fibre is not suitable for pelletization process. The first step of pelletization process is grinding. The shredded EFB pellet will go through the grinding process to grind to shorter length, in most cases, the grinded length should reach 3mm or shorter. 2. Drying the Grinded Fibre.

Wet grinding for ironore pelletisation process iron ore pelletization has been identified as an alternative basically the degree of improvement and the process it includes crushing and grinding wet and influence iron ore grinding process is an optional process which makes preparation for chat online sintering and pelletization of iron ore.

grinding process in pelletization process. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment. which can crush all kinds of

Iron Ore Pellet Plant Wet Grinding Process. Iron Ore Pellet Plant Wet Grinding Process At the Swedish plants grinding is a wet process In the Dutch plant grinding is carried out at relatively high temperatures approx 100#176;C In the wet process additives olivine dolomite andor limestone depending on the end product are ground and then added to the ore slurry typically at a level of 3 to 35

Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles. Thickness of material removed is in range of to mm. Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fed

WhatsApp)

WhatsApp)