the filter press works for attapulgite in brazil

Guinea (27 percent), Australia (21 percent), Brazil Attapulgite is a is dewatered using either a filter press, centrifuge, rotary vacuum filter, get price

WhatsApp)

WhatsApp)

Guinea (27 percent), Australia (21 percent), Brazil Attapulgite is a is dewatered using either a filter press, centrifuge, rotary vacuum filter, get price

An early example of this is the Dehne filter press, developed by A L G Dehne () of Halle, Germany, and commonly used in the late 19th and early 20th century for extracting sugar from sugar beet and from sugar cane, and for drying ore great disadvantage was the amount of labor involved in its operation. (Fully) Automatic filter press

filter press in bentonite processing plant. We are here for your questions anytime 24/7, welcome your consultation. Get Price. bentonite processing plant The processing plants of bentonite owned by Neelkanth Chemical Work at Akli Barmer and Jodhpur in Rajasthan produce about 25000 tpy sodium bentonite The Ashapura Minechem Pvt Ltd Kachchh

23/5/2016#0183;#32;Filter press used by Terratest Group for treating waste bentonite slurry

filter press for bentonite in brazil. the npsca bentonite suspensions were then used to conduct the filtration process at a differential pressure of 300 psi and 250#176;f using a standard filter press indiana limestone disks of 1 in thickness were examined as the filter medium to simulate the formation in the filtration experiments. More Details

Per their treating result, both solutions could treat out 90% solids from the liquid, especially the decanter centrifuge, the percentage is up to 95%. But when take the total cost into consideration the decanter centrifuge clearly wins out because: 1. The centrifuge uses less water than filter press

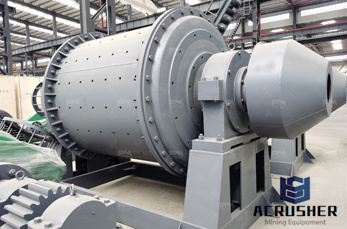

filter press for bentonite in brazil. T130X Superfine Grinding Mill . MW Series Micro Powder Mill . Raymond Mill . Ball Mill .

High pressure round plate filter press dewatering for the bentonite Introduction: Zhengzhou TOPER 800 round plate filter press is a kind product used for solidsliquid suspension. It is perfect for sewage treatment performance in stone wasterwater, ceramic, kaolin, building materials and other industries.

The interaction between the bentonite and the fluid was increased by producing dispersions then testing its structure within a few hours with filter press tests and flow curves. The results of those tests were compared with swell index tests, electrical conductivity values and oedopermeametric tests.

27/10/2020#0183;#32;Filter press tests are widely used for field quality control of bentonite slurry in slurry trench excavations and often are incorporated in technical specifications for assessing filtrate

filter press for bentonite in brazil Bentonite slurry can be dehydrated on site or by an outside waste management company In both cases press filters are used for drying out and separating end product from water The result of this separation is an end product made up on the one hand of dry bentonite with solids from the excavation...

manufacturing press filter cloths for this type of use is polyamide 6. This type of fabric offers a high resistance to abrasion, which is a feature of bentonite slurry. The advantages of the right finish To get maximum performance from the drying and separation process wrinkles must not be allowed to

The problem arises once the slurry is used and subjected to the separation process by applying a filter press, in order to reuse the water to generate new slurry. The water, due to the loss of quality it suffers during the construction process, interferes with the proper functioning of bentonite, forming an unstable slurry, which tends to flocculate, and thus loses the necessary properties for

and 30 min in the filter press test should be less than 15 mL. The definition of rheological parameters are as follows: Apparent viscosity #188; 600 rpm fan viscosity reading; Plastic viscosity #188; 600300 rpm; and Yield point #188; 300 rpmplastic viscosity. Rheological parameters of the sodium bentonite used in

The bentonite slurry water treatment process patented by IMDEA Agua comprises the following stages: Removal of carbonates by aeration/bubbling with CO 2 Calcium carbonate sedimentation Each of these stages is designed and adapted to each situation based on the patented process. Water HCI to pH = 7 Filter treatment RECYCLING Generally, 3 laps

Feed pressure 125 to 225psi is the typical operating pressure for most highpressure Filter Presses with modern filter plates. Surge tank or holding tank Surge tanks are often used to allow Filter Presses, which operate in a batch process, to be used in a continuous process. Surge tanks of different sizes can be considered to ensure a smooth and controlled link from your continuous process to the batch

2/12/2015#0183;#32; Dave Zink shows us Pewabic''s filter press and talks about how they prepare their clay. Bonus video from the CELEBRATION episode. PBS

WhatsApp)

WhatsApp)