cement plant cost Page 1 of 2

#0183;#32;Re: cement plant cost. Clark, you have considered 60 / Ton, Asian countries like india would get same cement plant with 35 / ton. if I am not wrong.

WhatsApp)

WhatsApp)

#0183;#32;Re: cement plant cost. Clark, you have considered 60 / Ton, Asian countries like india would get same cement plant with 35 / ton. if I am not wrong.

The company is also planning to build a township for their employees in the proposed cement plant The company proposes to expand its clinker capacity from MTPA to MTPA along with Waste Heat Recovery System (WHRS) of 27 MW at its Jayanthipuram plant in Krishna District at a cost

#0183;#32;We have million tonne grinding capacity in the East, where Salboni in West Bengal has mtpa capacity and Jajpur in Odisha has mtpa. Currently, these plants use lowcost clinker from

Plant will have a VRM of MTPA capacity. The plant will be located in an area of 40 acres in SIPCOT Industrial Estate The principal raw materials are Clinker, Slag and Gypsum. The major raw material, Clinker will be met from Cement plants of JSW. Water requirement of the plant is 500 m3/day and will be met from SIPCOT supply

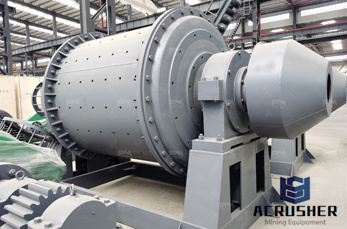

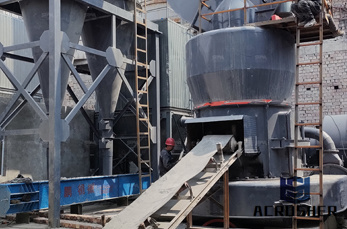

Cost Of Setting Up Cement Plant Per Mtpa. Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment. 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and

NCL cement plant is supported by their captive limestone mines NCL present installed capacity of cement plant is million tonnes per annum (MTPA) of clinker and MTPA of cement. NCL is manufacturing Ordinary Portland Cement (OPC), and Portland Pozzolana Cement (PPC). To meet the increasing demand of cement, both in the domestic and

cost of putting up one million tonne greenfield cement plant in cost of setting up cement plant per MTPA in Delhi, India. OCL India Ltd. India with an existing cement production capacity of million tons per annum

Graph 1: Indian cement production in the first nine months of the year, 2015 2019. Like ICRA it too picked up on low cost housing declaring it to be a key cement consumption driver. The sale of the former for plants in east and central regions has been linked to all the major local producers,

In December 1999, GACL paid Rs billion to acquire a 51% stake in Delhi based DLF Cement. DLF Cement had started its operations in 1997 in Rajasthan with a plant capacity of mtpa. After this merger, GACL became the fourth largest cement manufacturer in India after ACC, Lamp;T and Grasim.

Vijaynagar. JSW Cements first plant was set up at Vijayanagar, Bellary in Karnataka with a capacity of MTPA in 2008. Its capacity was boosted to MTPA in the year 2017 and was enhanced further to MTPA in the year 2019.

For updated information, please visit SUCCESSFUL USE OF ALTERNATE FUELS IN CEMENT PRODUCTION Madras Cement''s Alathiyur plant Use bioenergy through burning of coffee husk amp; cashew nut shells Annual cost savings of US million India Cements Ltd''s Dalavoi plant Use Low Sulphur Heavy Stock (LSHS) sludge as alternate fuel Annual savings of US 6,500

#0183;#32;The India Cements Ltd. he said ICL required about 500 hectares for mining and another 200 acres for the integrated cement plant in Madhya Pradesh. taking the total capacity to almost 20 MTPA.

India''s cement production is expected increased at a CAGR of per cent between FY1622, driven by demands in roads, urban infrastructure and commercial real estate. The consumption of cementin India is expected grow to at a CAGR of % from FY16 to FY22.

cost to set up mini cement plant in india . mini cement plant cost in india. aug 1, 2014 although the indian cement industry has some multinational table 1: capital cost to set up 1 mtpa cement

crushing cost for 1 mtpa quarry | stone crusher quarry. garnet mineral crusher ecuador, get price gt;gt; quarry crusher. nsic project on cement industry of capacity 1 mtpa; tracked crushing plant

#0183;#32;The Indian cement industry is dominated by a few companies. The top 20 cement companies account for almost 70 per cent of the total cement production in the country. A total of 210 large cement plants account for a cumulative installed capacity of over 410 MT, with 350 small plants accounting for the rest.

Successfully led Project execution work of New Jamul integrated cement plant project (worth INR 2000 Cr) MTPA 9000 TPD Clinkering line, MTPA cement grinding and packing plant line amidst some major challenges like Cash flow issues of prime contractor, high work force turn around, interface issues with existing plant layouts/operations amp; social political pressure etc.

#0183;#32;It takes around US 120140 per tonne to set up a cement plant. This has risen from around US 100 per tonne 34 years back. Given the rising cost of land and its unavailability, rising costs of equipment and engineering services, this capital cost to set up cement capacity is only going to rise.

This case discusses in detail the manufacturing and logistics activities of Gujarat Ambuja Cement Limited (GACL), one of India''''s leading cement manufacturing companies. The case describes how GACL has become the cost leader in the industry. It outlines the innovative and unconventional ways used by GACL for productivity improvement, pollution control, better distribution and cost cutting.

WhatsApp)

WhatsApp)